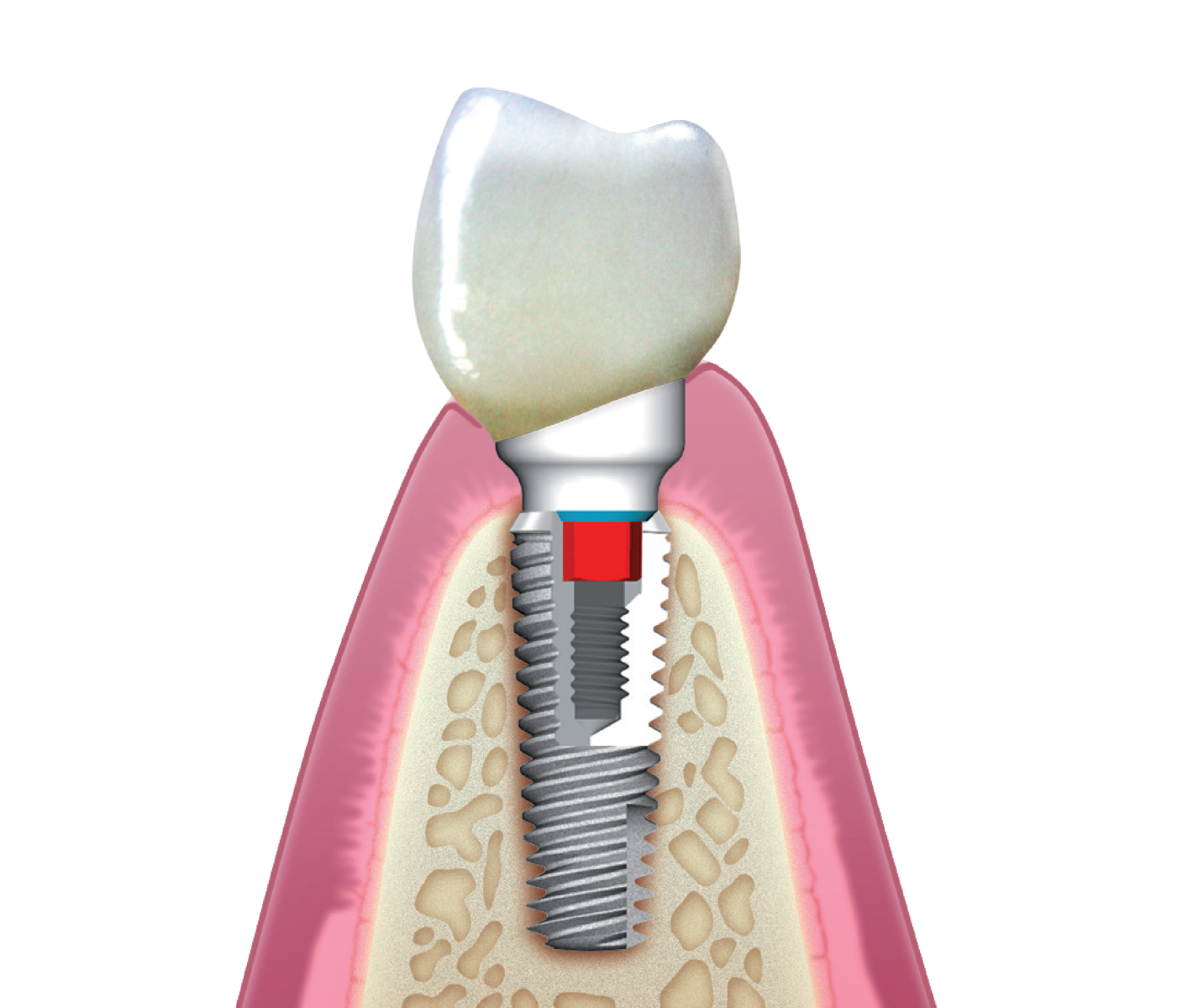

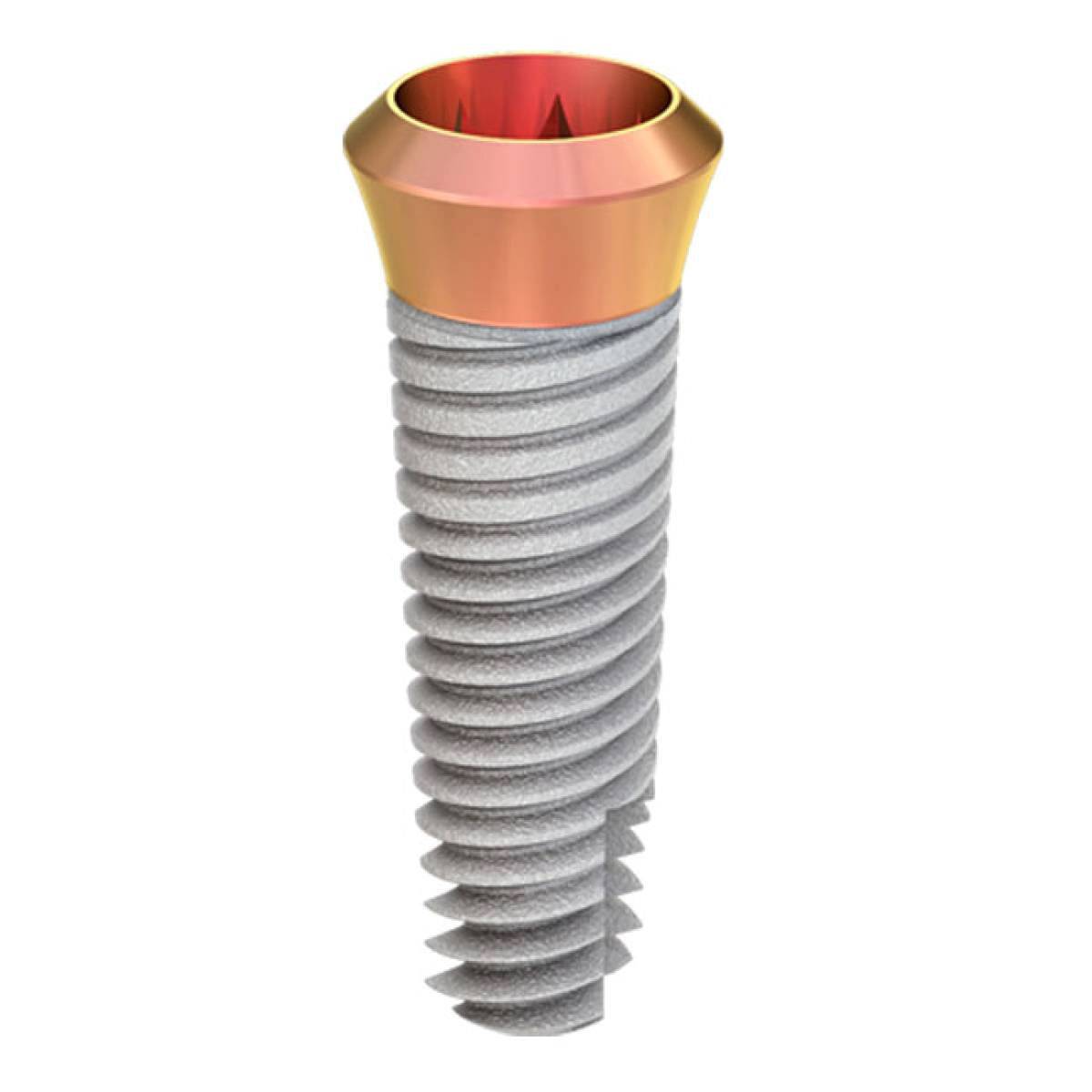

The TRI® Dental Implant System integrates four essential technology features. Each feature aims to provide maximum performance and lasting quality for the treatment of the dentist. We combine these elements in the TRI® Performance Concept.

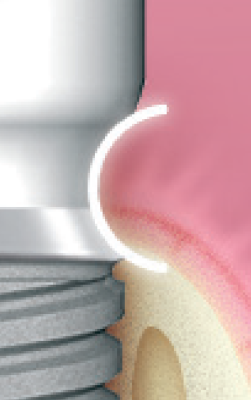

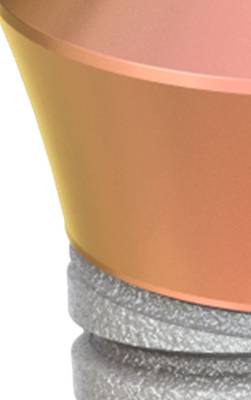

TRI® SOFT TISSUE CONCEPT

For long-term esthetic results.

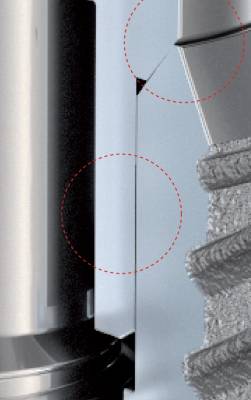

• Integrative platform-switch concept to preserve the crestal bone

• Consistent soft tissue management within all prosthetic components

• Homogeneous transition between implant and abutment to avoid «dirt pockets»

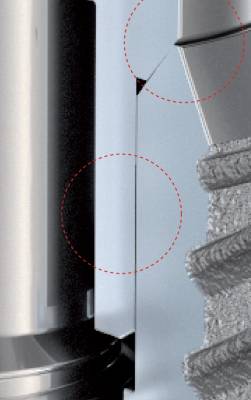

TRI® FRICTION

For a secure connection.

• Secure abutment stability through a dense tapered press fit

• Elimination of micro-movements between implant and abutment

• Internal hex for guided abutment positioning

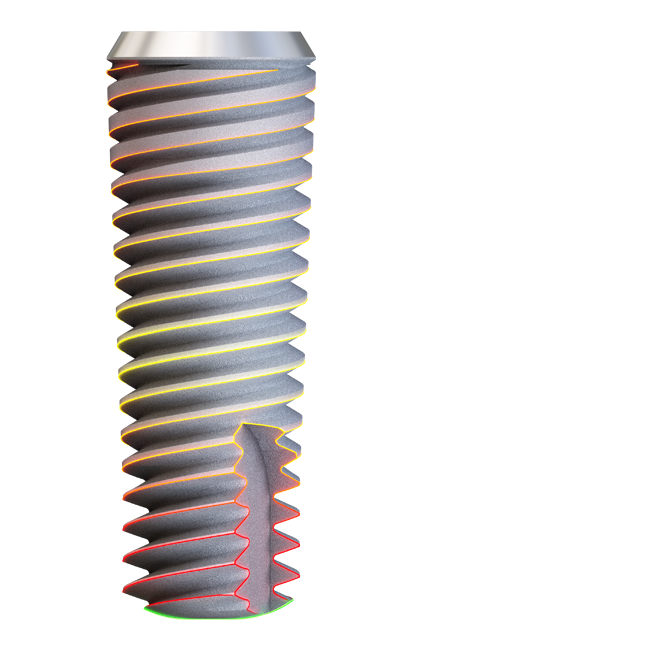

TRI® BONEADAPT

For immediate stability.

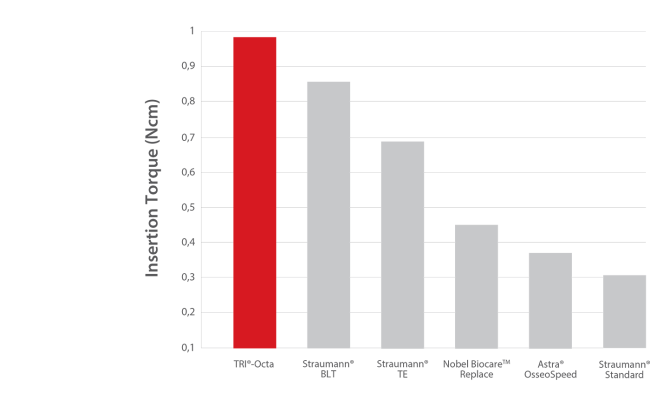

• High primary stability through a tapered implant body with self-cutting thread

• Bio-mechanical bone-adaption with maximum bone-to-implant contact

• Optimized conservation of the cortical bone through macro-thread design

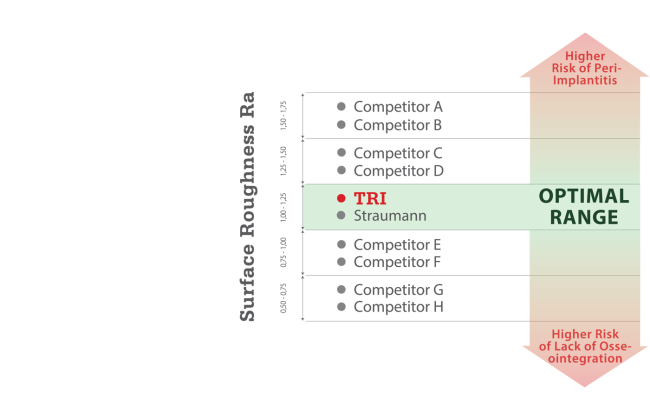

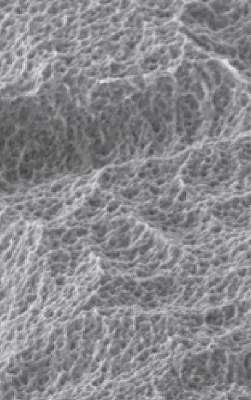

TRI® SBA SURFACE

For predictable osseointegration.

• Fast and reliable osseointegration

• Industry gold standard for secure osseointegration for more than 20 years

• World‘s most scientifically proven surface technology.

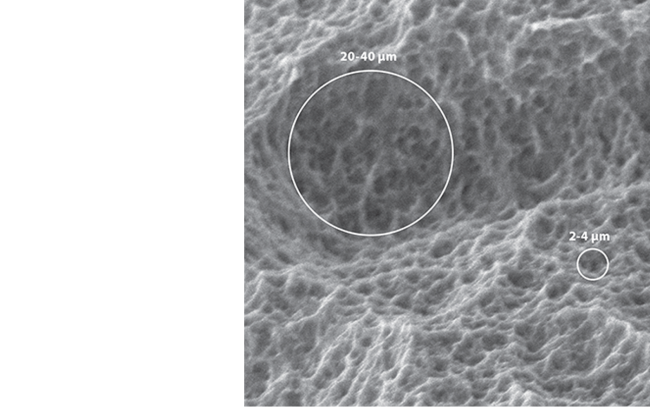

SBA: Sand-Blasted, large-grit, double Acid-etched

The soft-tissue interface is unique and innovative at the same time. The continuous platform switch allows for a consistent and tight soft tissue seal around the implant abutment connection. All prosthetic components integrate a consistent emergence profile – covering all components, from impression post and healing cap to the final abutment.

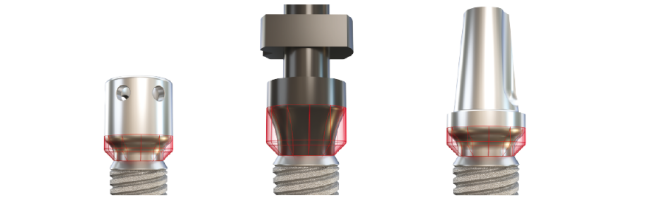

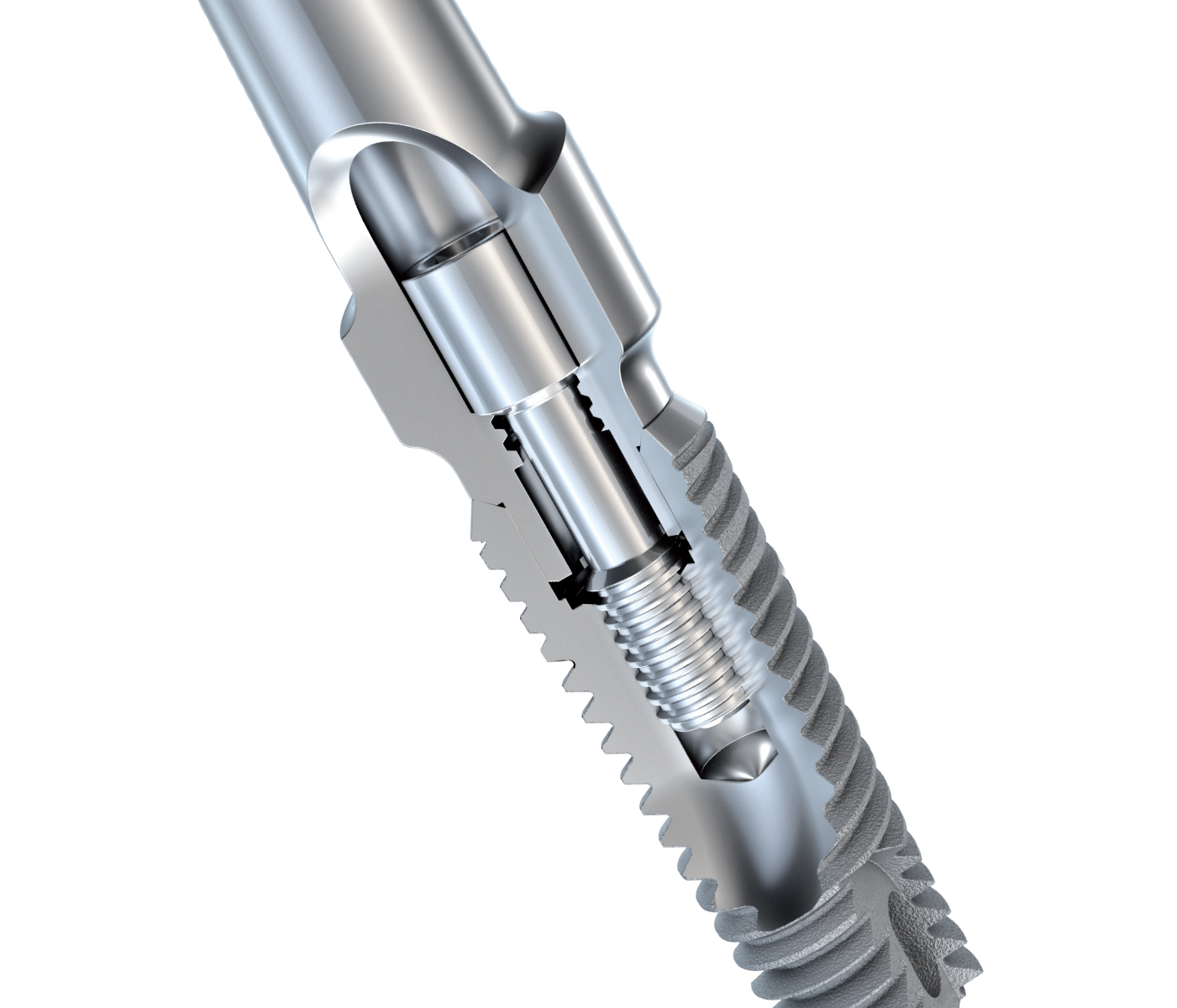

TRI® Friction is a technologically unique prosthetic connection and an integral element of the TRI® Performance Concept. A production tolerance of 0.006 mm guarantees the perfect and highly precise t of the prosthetic components with long-term stability.

• Press fit for maximal abutment stability

• Avoid micro movements between implant and abutment

• No screw loosening through rotational stability

• Improved handling through retention of the abutment even without screw

Internal conical 45 degree connection to eliminate the micro-gap

Frictional internal hexagon connection for maximum rotational and axial stability

The TRI® SBA (sandblasted, large grit, acid-etched) surface is one of the industry gold standards for more than 20 years. It is created by blasting the implant surface under pressure with corundum particles. In the final step the surface is acid-etched twice in order to attain a medium roughness.

Gingiva coloured implant collar

The Tissue-Level implant features a 1.8 mm machined implant collar for optimal esthetic results in the posterior area.

Machined implant neck

The Bone-Level implants feature a 0.5 mm machined neck in the crestal area.

Medium roughness

The entire implant body is blasted with coarse-grained corundum particles of 200–400 micron before being double acid-etched.